Vivobarefoot is a wildly popular shoe brand founded by Galahad and Asher Clark of the Clark shoes empire. The shoes are outrageously expensive ––about twice the price of leading fashion sports brands such as Nike, yet loyal customers come back time and time again to buy shoes that give the most true-to-barefoot experience in a shoe.

Vivo is now collaborating with an Israeli-Italian company Balena which is making a method and material so that shoes at the end of their lives will compost. It should be said that even the plastic parts of Vivo’s shows start to disintegrate anyway after a year.

What are barefoot shoes?

They have wide area for your toes to open out. The soles have zero padding, and just a thin layer of rubber between your foot and the world. No support. Because “you are the technology” as the slogan goes. Our feet, essentially, are built to support our backs and bodies. Modern shoes, Vivobarefoot claims, can actually damage your feet and body by changing your gate, and by putting pressure on areas of your body when running like your knees.

My son has been wearing Vivo shoes for 7 years and so have I. The rubber on the soles of the shoes wear out before the rest of the shoe. So if rubber and plastics aren’t going to last a lifetime, we can say it’s time to usher in the idea of footwear that can melt back to the earth.

Vivobarefoot says they have been prototyping 3D-printed footwear since 2019. Brand co-founder Asher Clark previously called the development of a 3D-printed shoe “an obsession”. The process involves 3D-printing the harder parts of the shoe such as the sole, then 3D-knitting the upper part. By 3-D printing, essentially shoes can be customized to a customer’s foot in the color choice they want.

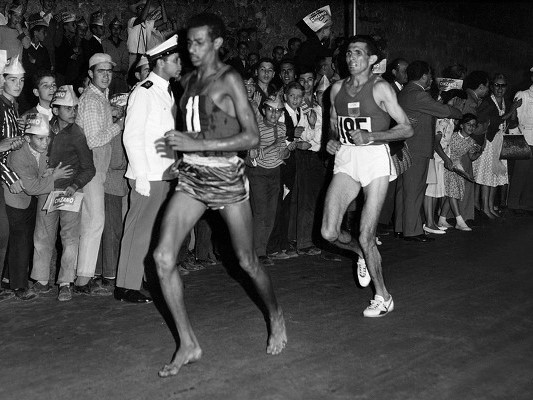

Read related: the 10 best marathons in the Middle East

By making shoes to measure, less material is wasted and product longevity is likely enhanced due to the shoes fitting the wearer perfectly. This translates to reduction in energy use and greenhouse gas emissions across the product value chain, according to companies that assess product life cycle.

Through its new partnership with Balena, Vivobarefoot is aiming to create 3D-printed shoes made with material that is both compostable and recyclable. Balena will apply its ‘BioCir flex’ material to the partnership. This material includes at least 50% bio-based content.

VivoBarefoot’s Clark said: “The world doesn’t need new shoes. We need a new system and new materials.”

Banela’s founder David Roubach said that there “is a need to advocate for a clearer circular economy model with a fundamental change in the materials we use” to reduce waste in this sector.

Billions of pairs of shoes are made globally each year. And most of these get thrown out as a by-product of fast fashion. That’s why there are so many flipflops in the Syechelles. If you have a business idea to work with a biodegradable material for rubber ducks and flipflops on a cruise line, you have a new impact company.

More on Balena here.