For years, consumer electronics companies have talked about reducing plastic. What’s been missing is a way to do it without compromising performance, safety, or scale. Of course we’ve been faithful on reporting on novel technology and applications of bio-plastics, that used by Stella McCartney, which is made from mushrooms, or bio-plastics made by Tipa. But this is a drop in the plastic bucket.

This week, Sony Corporation announced what may be one of the most consequential, and least flashy, breakthroughs in sustainable manufacturing: the creation of the world’s first fully visualized global supply chain for renewable plastics designed specifically for high-performance audio-visual products.

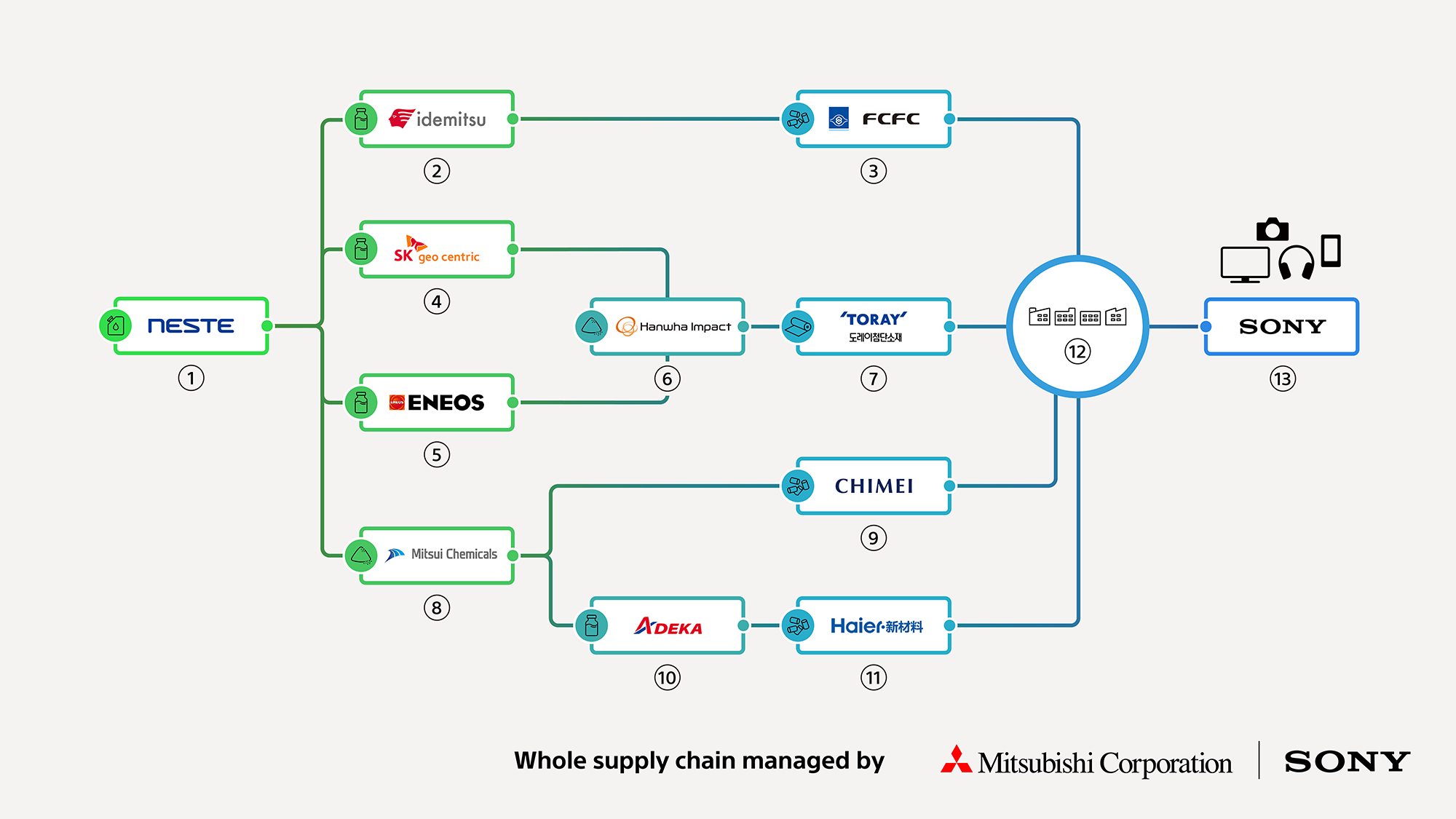

Fourteen companies across five countries and regions have joined in and these are spanning raw materials, chemicals, polymers, additives, and manufacturing. They have aligned to replace fossil-based plastics with biomass-derived alternatives, not in theory, but in products Sony plans to launch globally.

Why this matters more than recycled plastic

We know that most plastics do not get recycled, despite our best intentions to put our bottles in the recycling. With electronics, it is more complicated: Electronics are plastic-heavy for a reason. Casings, optical components, flame-retardant housings, and internal parts require tight tolerances, heat resistance, flame resistance, and optical clarity. These properties are difficult often impossible to create using mechanically recycled plastics alone.

That limitation has quietly stalled progress. Sony and its partners tackled the problem upstream by redesigning the entire materials pipeline, starting not with finished parts, but with renewable chemical feedstocks. Using a certified mass-balance approach, biomass-based inputs such as renewable naphtha are introduced at the earliest stages of chemical production, then tracked through each conversion step — from monomers to resins to finished components.

The result: plastics with the same performance characteristics as virgin fossil-based materials, but with a significantly lower carbon footprint.

One of the most important aspects of the initiative is transparency. High-performance plastics typically pass through dozens of opaque steps, making it nearly impossible to calculate or verify emissions. By mapping and fixing the supply chain end-to-end, Sony and its partners can now track greenhouse gas emissions across the entire lifecycle, enabling real carbon accounting rather than estimates or offsets.

The supply chain includes chemical and materials heavyweights such as Mitsubishi Corporation, Neste Corporation, Toray Industries, Mitsui Chemicals, Idemitsu Kosan, ENEOS, Hanwha Impact, Formosa Chemicals & Fibre, and SK Geo Centric, among others.

Each partner handles a precise step: renewable naphtha, styrene monomer, para-xylene, PET resin, polycarbonate resin, flame retardants, and PC/ABS blend, all engineered to meet electronics-grade requirements.

This level of coordination is rare, and that’s why the announcement matters. It shows that renewable plastics are no longer a niche materials problem, but a solvable industrial systems problem.

Sony frames the initiative as part of its “Creating NEW from reNEWable materials” project, aligned with the company’s broader Road to Zero environmental plan targeting net-zero environmental impact by 2050.