Choosing the right air operated double diaphragm pump for your needs can make a big difference in the success of your operation. Knowing what features to look for helps you find a pump that meets your specific requirements and works well with different types of fluids and conditions.

There are many models and suppliers available, so looking at an online supplier of wilden air operated double diaphram pumps allows you to compare different options more easily. Understanding the basics will help you make a confident decision as you shop for the best pump for your job.

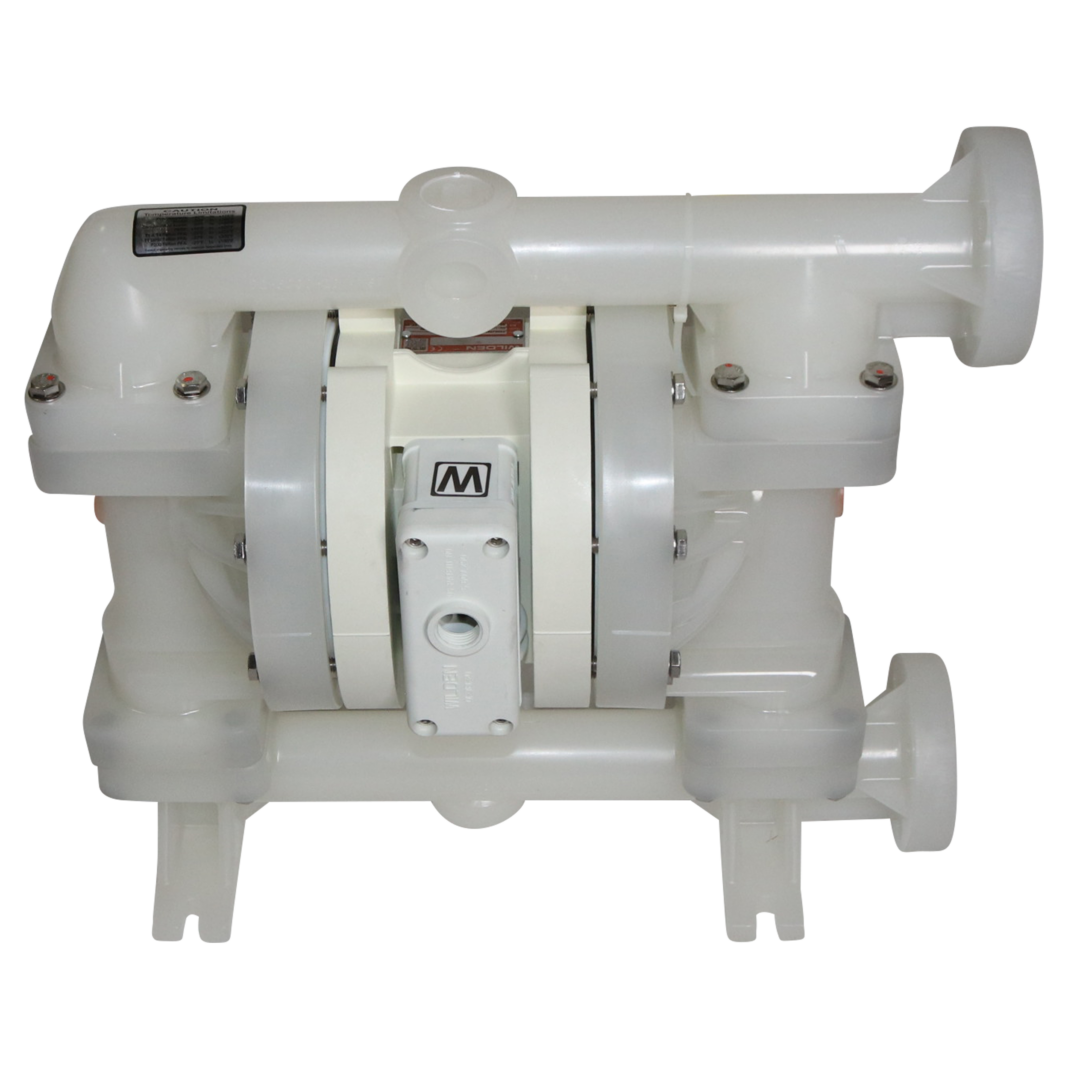

Pump Material Compatibility with Fluids

You need to match the pump materials with the fluids you plan to move. Different fluids can cause wear, corrosion, or chemical reactions if the wrong materials are used. Always check the fluid’s temperature, abrasiveness, and chemical makeup before choosing a pump.

Metals like stainless steel may be better for some chemicals, while plastics like polypropylene work well with others. Diaphragm and seal materials also vary, so check what’s most compatible with your liquids.

Choosing the right materials helps your pump last longer and work better. This step prevents leaks, breakdowns, and unnecessary repair costs. Always check chemical compatibility charts and consult with a professional if you have any doubts.

Diaphragm Durability and Wear Resistance

When looking at air-operated double-diaphragm pumps, it is important to check how long the diaphragm will last. A durable diaphragm helps reduce the need for frequent repairs and unexpected downtime.

Diaphragms can wear out from repeated movement, chemical exposure, or abrasive materials in the fluid. Choose materials that handle your fluid’s temperature, chemical makeup, and any gritty particles.

Common diaphragm materials include rubber, Teflon, and other flexible plastics. Each one has different levels of resistance to chemicals and wear. If you use the wrong material, it may fail quickly, leading to leaks or pump breakdowns.

Checking the design and thickness of the diaphragm can also help. Thicker or reinforced diaphragms often last longer in tough applications. Always match the diaphragm type to your specific job to get the best life and performance from your pump.

Air Valve Efficiency and Design

When choosing an air operated double diaphragm pump, you should pay close attention to the air valve. The air valve controls how air is directed through the pump, affecting its energy use and how smoothly it runs.

A well-designed air valve helps the pump cycle efficiently. This means fewer slowdowns or stalls during operation. Pumps with smooth-shifting air valves also tend to need less maintenance over time.

Look for air valves made of durable materials. This helps in longer wear, especially when the pump is used in tough environments.

Check if the air valve allows easy access for cleaning or replacement. User-friendly designs let you fix problems quickly, which reduces downtime.

The size and configuration of the air valve should match your application. Adjustable or self-lubricating valves can give you better control and smoother performance.

Flow Rate and Pressure Capacity

When choosing an air-operated double-diaphragm pump, you should pay close attention to flow rate and pressure capacity. These two factors tell you how much fluid the pump can move and at what force.

Check the maximum flow rate, usually measured in gallons per minute (GPM). Pick a pump that meets your system’s needs without being too small or too large for the job.

Look at the pressure capacity as well. You want a pump that can handle the highest pressure needed for your application. Too little pressure means your pump may not move fluid efficiently.

Flow rate and pressure are often linked. Increasing the air supply can boost both, but it is important not to exceed what your setup can handle. Adjust the air supply for consistent output when needed.

Checking these features helps make sure the pump works properly and matches your requirements.

Ability to Handle Abrasive and Viscous Fluids

When you choose an air operated double diaphragm pump, it is important to check how well it can move abrasive and thick fluids. Some pumps are made with tough parts that resist wear when handling grit, slurries, or other rough materials.

Look for pumps with diaphragms and valves made from strong materials. This helps prevent damage and keeps the pump working for longer periods.

A good pump should also handle fluids with high viscosity without getting clogged or slowing down too much. This is useful for industries that work with heavy oils, pastes, or sludges.

You want a pump that can keep its performance steady, even as it moves thick or grainy fluids. By looking for these features, you can help reduce maintenance needs and keep your system running smoothly.

Ease of Maintenance and Repair

When choosing an air-operated double-diaphragm pump, look for designs that make routine care simple. Pumps with fewer moving parts are usually easier to clean and take apart for inspection.

Check if the pump allows easy access to key parts, like diaphragms and valves. This helps you spot wear or damage early and replace parts without a lot of effort.

Some pumps use standard repair kits. Using these kits can make repairs quicker and reduce downtime. Clear instructions from the manufacturer also help you carry out maintenance without confusion.

Pay attention to how much air or fluid is leaking during use. Excess leaks can indicate parts that need attention. Regular checks keep your pump working well and can prevent surprise breakdowns.

Conclusion

When selecting an air-operated double-diaphragm pump, focus on features like material compatibility, flow rate range, and ease of maintenance.

Check for design elements that allow for simple cleaning and fast part replacement.

Review the pump’s ability to handle dry running, solid content, and various fluid viscosities.

You improve the safety and efficiency of your system by matching the pump’s features to your application’s needs.