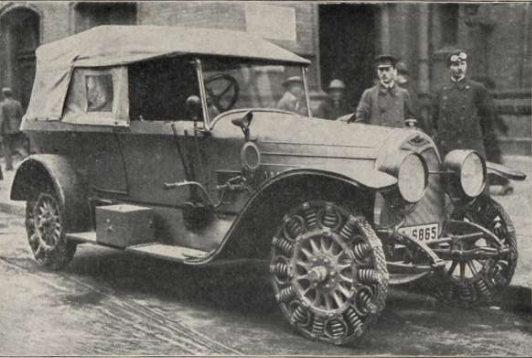

What happens when you need something, but you cannot get it anywhere – like tires for your car. You can’t buy them at any price. What do you do then? Stop driving your car? Stop plowing farmer’s fields because you can’t find new tires for the tractor? Imagine a world without tires? Remember Eisenreifen?

A car in Germany with “Eisenreifen”— steel tires — during World War I. From Der Weltkrieg in Bildern und Dokumenten by Hans F. Helmolt.

The world’s community of nations may wind up facing that situation as the global supply of natural rubber is now at risk from different factors, climate change, fungal disease that is killing Para rubber trees in the five Asian countries that 90% of the world’s natural rubber comes from.

Major Industries to Face Natural Rubber Shortage Globally

CNBC covers the “rubber apocalypse”

Last year CNBC covered a story on the rubber shortage and what it means for Americans. I included the video below and you can assume if it’s a problem for America it will be your problem too.

Ohio State University Professor Katrina Cornish, told CNBC: “We could be on the cusp of a rubber apocalypse.”

The global rubber market was valued at nearly $40 Billion in 2020, but one analysis predicts the natural rubber market could be worth nearly $68.5 Billion by 2026.

Grow for sustainable rubber

Cornish is CEO of Energyene where she works to improve the natural rubber content of two alternative plant species that yield a high quality latex. At Ohio State University she works with their Program of Excellence in Natural Rubber (PENRA) to develop higher yields from plant species. One of them is an annual called guayule.

Guayule can be the future for sustainable rubber

Guayule or Parthenium argentatum in Latin is a perennial woody shrub in the family Asteraceae that is native to the rangeland area of the Chihuahuan Desert, including the southwestern United States and northern Mexico.

Like hemp production was heralded as the future 30 years ago, guayule could be the next new cash crop for struggling farmers.

PENRA has developed a water based extraction process to separate natural rubber from plant materials like guayule without the use of chemicals.

Still don’t care? In 2020 the European Tyre & Rubber Manufacturers Association included natural rubber in the list of critical raw materials, reconfirming its economic importance and the need for supply diversification.

The tire industry alone absorbs about 76% of all the natural rubber produced globally, their 2020 report detailed: “Today there is no substitute for natural rubber from Hevea (Hevea brasiliensis) trees that could be used in all its current applications.”

If you’ve ever visited Thailand you will see smallhold farmers growing and harvesting milky latex from Hevea trees planted at side of the road for easy access.

Natural rubber is an incredibly important raw material for the European tire and rubber industry and is a key enabler for several industries – especially automotive.

In 2020, 2 million tons of natural rubber was imported into America and used in 60,000 products that depend on it. According to Cornish that same year a million Hevea rubber trees died from fungal leaf blight, causing a 10% drop in the global natural rubber supply.

America has no capacity at this time to produce natural rubber, and depends on five Asian countries that export it, China and Vietnam among them.

Turning American into exporter of natural rubber

White Tiger Farms, an agriculture enterprise that I am building in Oregon, will tackle that task of building both production of the two alternative plant species that yield a high quality natural rubber, and the industrial process to sustainably harvest it. We will help grow 95% pure raw natural rubber product for America’s current and future needs for this critical commodity of vital national importance.

Our goal is to scale up capacity to turn America from being an importer of natural rubber to become the first nation to export natural rubber made from these two alternative plant species.

At this time there are over 100,000 deeded acres of former ranch properties up for sale in Oregon, ideal for repurposing into farm sites to use high density vertical growing systems, and geodesic greenhouse domes from in Ashland, Oregon, as well as larger domes to 150 meters in diameter from Geometrica to grow plants year round, with sustainable harvests of plant materials every 90 to 120 days to turn into raw natural rubber, working with PENRA and Professor Cornish.

Cornish and her team have developed cultivars of dandelion that yield up to 10% content of natural rubber per dry weight of harvested material. She says that these cultivars that work in America will also work in the Middle East.

Rubber dreams for America- what do we need?

Let’s say it takes ten plants to yield a pound of natural rubber, and America uses two million tons per year, which equal four billion pounds, how many plants will be needed to meet that amount consumed per year?

Taraxacum kok-saghyz, often abbreviated as TKS and commonly referred to as the Kazakh dandelion, rubber root, or Russian dandelion, is a species of dandelion native to Kazakhstan, Kyrgyzstan and Uzbekistan, that is notable for its production of high quality rubber. It grows well in America.

Our operating plan is to begin by growing thousands of TKS dandelion and Guayule, the other plant that yields a high quality, non-allergenic natural rubber, in our onsite greenhouse domes to be set up on farm sites.

From those thousands of plants we will ramp up to grow millions of plants, and go on to raise billions of plants on farm sites locally and year round, with harvested material going to regional processing plants to produce raw natural rubber for American manufacturers.

Within five years we will establish production of the TKS dandelion for its content of natural rubber latex in its long, thick roots, and the desert rubber plant, guayule used in WWII to produce tires for the American military when Japan cut off Asian natural rubber sources.

Luckily Mexico was able to produce those tires from their cultivation of the Guayule rubber plants, known for their content of natural rubber granules in the cambium layer of their mature stems.

Within ten years we will no longer depend on natural rubber imports and will export to the growing global markets for natural rubber, made in America.

In 2020 the global demand for natural rubber rose to 17 million tons per year, the same year that saw a loss of a million rubber trees, and a 10% loss to the global supply.

What happens when demand is greater than the supply, the price per kilogram of raw natural rubber is bound to increase as more countries develop their local transportation sectors and put more cars, and trucks on the road, as well as jets into use, all depend on tires to run on.

Literally, the world’s economies run on natural rubber.

Doing your homework on sustainable rubber? Want to start growing?

For further research, these are websites I’d turn to:

Global Platform for Sustainable Natural Rubber

World Business Council for Sustainable Development