People who own cars want to at least have the option of taking an extended road trip, which has been a major barrier to the success of electric vehicles to date. Limited driving range and long battery charging times are two challenges that EV industry leaders have been working furiously to overcome, and a company from Israel believes they have devised an acceptable solution.

Phinergy’s air batteries made up of 50 aluminum plates can give EVs a range of up to 1,000 miles, according to Gizmag, with each plate providing enough energy for 20 miles. Weighing a total of 55 pounds, this fuel cell could be used in tandem with existing lithium-ion batteries, according to the developers, but the technology is far from ideal.

Gizmag notes that several companies have been trying to come up with mostly lithium-air batteries that have a longer range, in order to make electric vehicles more attractive to a wider audience.

Gizmag notes that several companies have been trying to come up with mostly lithium-air batteries that have a longer range, in order to make electric vehicles more attractive to a wider audience.

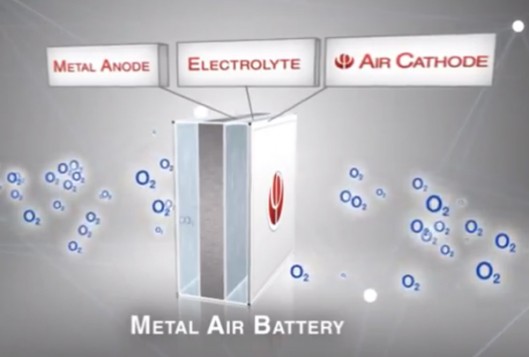

“These batteries offer significantly increased capacity in a more compact form factor by replacing bulky conventional cathodes, which contain the oxidizer within the battery itself, with lighter “air cathodes” that instead draw oxygen from the surrounding air,” writes Darren Quick.

But Phinergy has taken a different approach “with an air electrode with a silver-based catalyst and structure that lets oxygen enter the cell, but blocks out CO2. The result is an air electrode that Phinergy says has an operational lifespan of thousands of hours.”

Problem is, once the 1,000 miles of energy has been exhausted, the battery can’t be recharged. It’s a disposable solution, though Phinergy does not that aluminum is easily recyclable.

Critics responded to Gizmag’s post rightly question whether the energy required to process the aluminum outweighs the benefits of having a renewably-charged electric vehicle in the first place.

But the Israeli startup suggests that their technology, which could be commercially available by 2017, is best marketed as a backup for conventional, rechargeable lithium batteries.

Regular EV batteries can be used for day-to-day short distance travel, while Phinergy’s aluminum air battery would be used for extended trips.

While not entirely ideal, since we really do need to move away from our disposable culture, certainly this is a crucial step in the right direction. Meanwhile, in Tel Aviv, city officials are testing an EV rental program specifically designed for short range travel.

Such a program could help reduce emissions and congestion.

:: Gizmag

There was Israeli company “Better Place”, now former Better Place who developed EV based on rapidly replaceable battery. Pinergy with mechanically replaceable battery and/or core seems will face similar fate. It looks like the main driver behind this concept is quickie IPO!. From technological, energetic, and commercialization point of view it has many flaws. Historically, Air Aluminum batteries being used in emergency, and defense sectors because Aluminum has high volumetric energy density (reduces battery volume) and medium to low energy density per unit weight. In defense sector most of application included marine applications in submersible underwater vehicles because a common electrolyte is Sodium Chloride (Sea water) the battery simply flooded by sea water. It should be noted that Aluminum used Air Aluminum batteries is not a commercial grade Aluminum from which widow’s frames are manufactured, but specially developed Aluminum alloys containing Thin, Gallium, Magnesium ingredients. These alloys are patented by some companies developing their proprietary Air Aluminum batteries. The electrolytes are; Sodium Chloride (low potential 0.7V salty water), NaOH (~2.3V water base solution), KOH (~2.5V water base solution) as the result of electrochemical reaction in water based electrolytes Aluminum Hydroxide is formed and not Aluminum oxide. Aluminum Hydroxide initially forms gel covering the Aluminum electrodes (plates) thus effectively reducing current which can be withdrawn from battery. With the precipitation the Aluminum Hydroxide gel is transformed into Aluminum Hydroxide crystallites fallout which if the distance between Aluminum plates is small can form dendrites. Large volume, significantly larger than 50 plates occupy in Pinergy battery, of the electrolyte needed to be circulated through the battery to wash the gel from electrodes and dissolve Aluminum Hydroxide. Collection of the Aluminum Hydroxide dissolved in electrolyte may present some technological difficulties not foreseen.

From economical angle, in Israel and many European countries Gasoline prices are high due a heavy taxation, even if the price for 1 kg of Aluminum would be $2 still it is not economically viable even in this countries. In US and Asia the prices for Gasoline are significantly lower.

Yet, there is another angle, Energy density of pure Aluminum is 31MJ/Kg which is 8.61 kWh assuming 100% efficient conversion that is theoretically impossible, at best case limited to about theoretical 83%.

Energy density of Gasoline, Bio-Diesel is ~43MJ/Kg which is 11.94 kWh assuming 100% efficient conversion, which is also limited to 83%. Energy density of the Aluminum is only ~72% these Hydrocarbon Fuels can provide

The most economical way to refine Aluminum and to smelt Aluminum alloys, to produce Pinergy plates is ~15 to ~18 kWh/Kg not including excavation and transportation. So, the energy balance of 1Kg Aluminum is 8.61 kWh(at 100%) – 15kWh (production) = -6.39 kWh (negative)

The barrel of oil contains 1700kWh which is 12.8 kWh, refining of oil per 1kg of Gasoline consumes ~5.8kWh, it should be noted, that same ~5.8kWh are producing together with Gasoline Diesel, Kerosene (Jet fuel), Petrol gas and other products from of crude oil.

The energy content balance for Hydrocarbon fuels (Gasoline) is 11.94 kWh -5.8kWh (Refining) = +6.14 kWh, this is the major factor why Hydrogen-Carbon bond economy drives the world

And who will pay for negative balance of the Aluminum production invested energy? Pinergy is “Sacrificial Battery” it should be replaced by new (at least Aluminum), the Aluminum Hydroxide dissolved in electrolyte should be transported to a factory where it can be extracted as powder and recycled into Aluminum at energetic cost of ~3kWh per 1kg of Aluminum, and transformed back into Pinergy Electrodes (plates). And who will pay for all these? So, hold your horses, the Aluminum Economy is still not around the corner