Zurich-based RAFAA Architecture & Design propose the next generation of super sustainable solar power towers.

Zurich-based RAFAA Architecture & Design propose the next generation of super sustainable solar power towers.

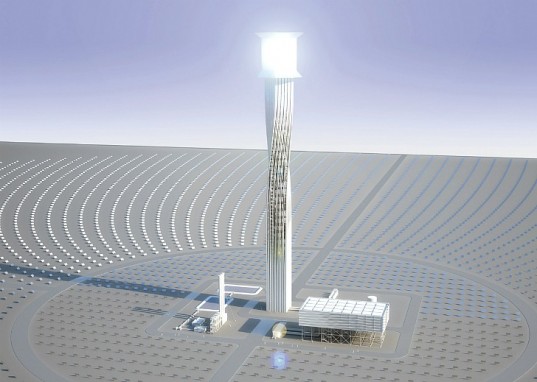

An often overlooked component of the growing number of solar power plants popping up in Egypt, the United States, Spain, and elsewhere is that someone was responsible for their design. Bright Source Energy recently solicited proposals from international firms for the Ivanpah solar plant in California that is currently undergoing construction. In particular, they are seeking the next generation of super sustainable concentrating solar power towers which we recently reported will be taller than earlier models to enable more efficient space management on new sites. RAFAA Architecture & Design from Zurich believe they have just the solution.

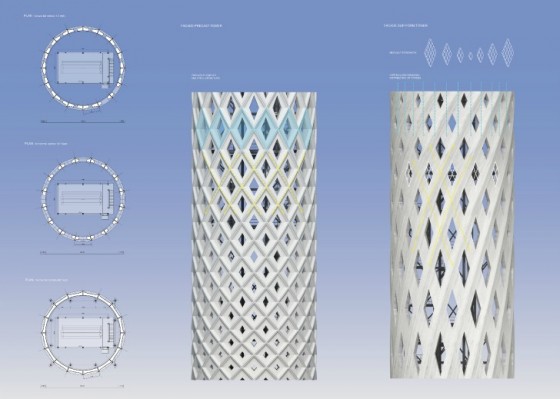

RAFAA submitted two options to Bright Source Energy. The first is a modular precast concrete tower that would be assembled on site. It resembles light waves wrapped in a helix, which is both beautiful and provides superior structural support. But since concrete has a high embodied energy footprint, it is not considered the eco-friendliest material.

The second option is significantly better for the environment, and the option that RAFAA supports. This square tower uses lightweight steel (which could technically be recycled and is therefore more economical and more sustainable than concrete) and has a twist in the middle. Option B would be pre-fabricated, and could easily be dismantled and used elsewhere if it outlives its usefulness at the solar power plant.

When complete, the Ivanpah plant will produce 392MW of electricity, a goal that hinges a great deal on the effective design of its towers. They have to be efficient and clever, but they should not be a blight on the natural environment. Other companies have submitted their proposals as well, and we hope that Bright Source will choose the most sensible and sustainable option!

:: Inhabitat

More on BrightSource Energy Projects:

Google’s Largest Investment Goes to BrightSource Energy

Now 39 Tortoises Halt Progress at BrightSource Ivanpah Solar Project

BrightSource Energy’s Earth Day Debut

images via RAFAA

I think these designs are aesthetically beautiful. However, I don’t understand how it could be concluded that the steel option is “more economical and more sustainable” than the concrete solution. Making such a judgment requires a comparative Life Cycle Assessment (LCA); it’s not so simple as noting that “steel can be recycled” (of course, so can concrete).

PCI has conducted comparative LCAs, and I can tell you that there are many details that must be studied for an application like this. How much energy and environmental impact would be associated with coating and periodically re-coating a steel tower over its lifetime to prevent corrosion? How much fabrication energy would be used simply to introduce the helical twist in the steel tower? What about using concrete made with little or no Portland cement (a main source of concrete’s energy and CO2 impact)?

I suggest that builders of such towers consult with competent representatives of the steel and concrete engineering communities who have performed the appropriate LCA studies, and not rely only on the opinion of RAFAA, in deciding which option to use.