Director of the Masdar City PRT project, Robbert from 2getthere talks to Green Prophet about Masdar’s modest fleet of driverless pod cars.

Director of the Masdar City PRT project, Robbert from 2getthere talks to Green Prophet about Masdar’s modest fleet of driverless pod cars.

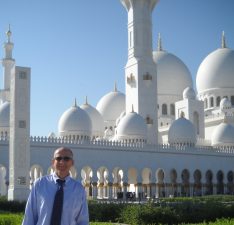

Hundreds of people lined up to experience Masdar City’s PRT at the first Market@Masdar (see our exclusive Masdar pictures), and Robbert was ready to answer their questions! A friendly face behind the enigmatic pod car so fiercely debated among skeptics and eco die-hards, Robbert compliments the fleet’s performance despite a higher than capacity turnout. Step in to learn more about Masdar City’s pod cars and other projects 2getthere hopes to roll out soon.

Robbert: we recently met at the first Masdar City Street Fair and Organic Market. Can you tell us what your role was that day?

As this was the first time the Market@Masdar was organized and it was unclear what could exactly be expected, 2getthere made sure her full site team was available that day. As Project Director the team requested me to be present as well, in order to have a knowledgeable person on the complete project at each station (our Operations Manager represented our organization on the North Car Park station). Essentially we assisted in making sure the operations at the station were running smoothly and that in case of peak demand people were sharing the vehicles as much as possible.

How many PRTs has 2getthere sold to Masdar and how are they managed?

In total 10 PRT vehicles (of which 2 are equipped with a luxury leather interior) and 3 FRT (Freight Rapid Transit) vehicles have been installed at Masdar. The system is operational 7 days a week, 18 hours per day.

At site there is a dedicated operations facility, with a control room and maintenance work space. 2getthere cooperates with Singapore based SMRT for the operations of the system. The maintenance is performed by 2getthere engineers with remote support from the offices in the Netherlands.

Can you give us a quick low down on how they work?

The vehicles basically operate according to virtual routes on a known layout of the area where they are allowed to drive. Once they start driving they continuously calculate their position by measuring the distance driven (by measuring the wheel revolutions) and the direction of travel (by measuring the steering angle and by use of a gyro). As this is somewhat inaccurate (through different weights, loads, wheel spin, etc.) it is necessary to calibrate the calculation with the actual position of the vehicle. For this purpose external reference points (passive magnets embedded in the road surface) are used. These are located approximately every two meters. The accuracy of driving is within 2 centimeters as a result.

At Masdar, how fast do the pod cars travel and how far?

The pods at Masdar are capable and tested up to the technical maximum speed of 40km/hr. However, the speed in day-to-day operations is limited to 25km/hr. During testing it became evident that the difference between the top speeds was only 13 seconds over a complete lap (North Car Park to MIST and return again).

While this difference was only marginal, there was actually a considerable difference in the amount of energy consumed – it is the last part of the acceleration that consumes most energy. To allow the vehicles to reach a longer range before having to recharge, it was decided to maximize the speeds for now at 25km/hr. Currently the range on a single charge is approximately 60 kilometers.

Were you happy with how the first market went? Masdar reported that “thousands” of people attended the event.

From the perspective of the PRT system the Market was an absolute succeas, and I believe more in general as well. The PRT system operated at 99,4% system availability throughout the day, carrying nearly 3.600 passengers. With the large numbers of visitors coming to Masdar, the demand was far larger than actual capacity, which resulted in waiting lines. People were advised of the possibility to take the shuttle bus to avoid the lines, but many lined up anyways to experience the PRT.

The actual capacity supplied exceeded the maximum design of the system in the simulations, for 10 hours straight in each direction of travel! This was attributable also to the willingness of people to share a vehicle (increasing the average occupancy) and the volunteers working at the station to ensure operations were running as smoothly as possible.

Where are your PRTs manufactured and how expensive are they to build?

The PRTs are manufactured in the Netherlands, with suppliers from Belgium, Italy, China and other countries contributing. They are manufactured and assembled by hand in plants where normal small-series cars are build (e.g. exclusive cars in limited series).

As the cars are part of a system, the costs should be compared based on system pricing. Automated systems are quite common on many international airports, but usually are a combination of heavy infrastructure (rail) accommodating large flows of passengers. The 2getthere system and the Masdar application are unique because they are realized for a fraction of the cost of the systems installed at airports.

Most people point out that any vehicle which relies on electricity is still contributing to greenhouse gas emissions; how would you respond to that?

It is better than the alternative, making it a logical step to take. In moving towards a more sustainable society, one step is taken at the time. An initiative like Masdar, with the PRT as part of it, should be embraced as a (larger) step in the right direction. Electric vehicles, whether automated or manually driven, are at the start of the product life cycle, where current cars are well advanced in theirs.

With the requirement for mankind to resolve the issue of energy consumption, the speed of the development of electric and automated vehicles will continue to increase, reducing greenhouse gas emissions further and further.

Word has it that 2getthere has a few other projects on the go. Can you briefly tell us about those?

These are exciting times for 2getthere. There are various projects that are close to a decision, with numerous others under discussion. Certainly the installation at Masdar, both in the speed of realization as well as the good system availability, is contributing to the ever growing interest in our products. We are very anxious to sink our teeth into the next project based on the learnings generated from the Masdar application.

More on Masdar City and its PRT/Pod Cars:

Ride a Pod Car and Meet Masdar City @Monthly Fair

Masdar’s Futuristic Eco-Pod Car Has Arrived

EXCLUSIVE: Masdar City Open House Photos

Could you post about your experience? We’d all like to hear about it!

I sho did! It was a pretty smooth ride, beeps in reverse, and goes at the touch of a play button. It’s comfortable too.

Love this interview Tafline. Did you take a ride in the podcars?