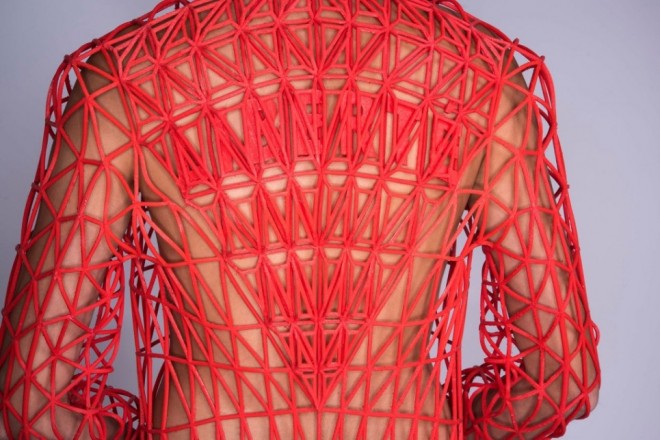

An Israeli fashion designer has created a new line of women’s clothing without a bolt of cloth. This summer, Danit Peleg released the world’s first 3D-printed couture using only a plastic thread-like material called Filaflex and Witbox printers. (Coco Chanel must be spinning in her pearls!)

The recent graduate from Shenkar College of Engineering, Design and Art told Global Voices, “My goal was to create a ready-to-wear collection printed entirely at home using printers that anyone can get. I’ve spent the past year searching for the best solution.”

The collection includes five unique outfits that foretell the future of fashion. Said Peleg, “Just imagine the potential… if you’re cold, print your own jacket. Traveling with no luggage? Just print your clothes in the hotel room. Will we soon be able to design, share, and print our own clothes directly from home?”

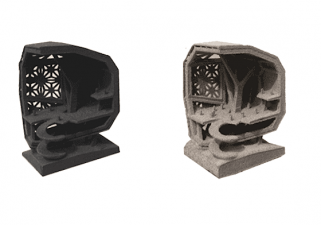

Three dimensional printing involves a sequential layering of material that bonds together to create a stacking effect of matter that conforms to specified measurements for solids and voids. The earliest 3D printing systems came on scene in the late 1980’s, with the first patented apparatus awarded in 1986. A growing number of competing companies invested heavily in research and development, quickly moving the technology beyond making simple prototype artifacts into specific tooling, casting and direct manufacturing applications.

The sector began to divide at the turn of this century. One branch focused on costly systems geared towards production of highly engineered parts aimed at aerospace, automotive, and medical sectors. Another zoomed in on 3D printers developed specifically as user-friendly, cost-effective desktop machines aimed at office use and priced below $5,000 USD in order to open the technology up to a much wider audience.

Peleg’s year-long journey into printable clothing began with trying to figure out how to create plastic with the flexibility of textiles. Online research brought her to Andreas Bastian’s Mesostructured Cellular Materials project on Thingiverse, which explored 3D printable patterns that allowed material to bend and stretch like bias-cut fabric. Steering clear of solid sheeting seemed to be the solution, she used triangular shapes before applying Bastian’s complex pattern.

In all, the designer estimated that she spent over 2,000 hours converting 3D digital files and printing the intricately punctured plastic sheeting – a single A4-sized swatch took 20 hours to print. Peleg predicts that as 3D printing technology becomes more affordable, with faster production times, users could download and print files at home as they do with two dimensional clothes patterns.

[youtube]https://youtu.be/3s94mIhCyt4[/youtube]

Accessibility to new tech brings rapid innovation. Green Prophet has reported on food and handguns and cars made from 3D printing. There are pet prosthetics and figurines made from photography that allow the blind to “see” snapshots. Now 3D printing in fashion is beginning to mature.

So – what to wear with your 3D printed frock? Some 3D printed makeup, of course.

All images from Danit Peleg website

Comments are closed.